- Smart innovative solutions

- Customer engagement from the start

- Our systems are built to last a lifetime

Our fully automatic bag-emptying unit can empty granulate filled bags of 25Kg. Pallets are placed at the front of the infeed conveyor with a forklift truck. After placing the pallet on the infeed conveyor, the conveyor will transport the pallet to the lift, here the lift will transport the pallet upwards to a shuttle with integrated grippers. The integrated grippers will grab a layer of 5 bags of the pallet and ride this to the emptying process. Here the shuttle drives the bags over rotating blades and a unique shaker system, this will cause the product to fall into the product hopper.

The capacity of these machines is between 10 and 30 tons of granulate per hour. This depends on configuration of the machine and product.

Pallet stacker

After emptying the whole pallet, the empty pallet will be pushed out with a pusher to the pallet stacker. Here the pallet will be stacked to a maximum of 15 pallets or a certain value. When this setpoint is reached the stacker will put the pallet stack on the conveyor and sent it to the pickup position where it can be picked up with a forklift.

Cleaning

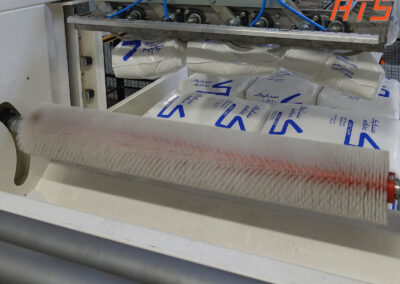

This machine is equipped with rotating brushes with height adjustment to clean the bottom of the bags. By transporting the bags from the lift to the emptying process the shuttle will ride the bags over rotating brushes. The brushes will move upwards until they meet the bags, because of the height adjustment it doesn’t matter if you use thin or thicker bags the bottom will always be cleaned nicely. The debris will fall into a waste funnel that can be connected to a vacuum cleaner.

In addition to the rotating brushes, this machine is also equipped with several air knives (on the shuttle, above the product hopper and more) during a cleaning cycle, any remaining granulate grains are blown away from dead spots.

Pneumatic transport over long distance

This bag-emptying machine is using pneumatic transport for transporting granulate with high capacity over long distances. There are in total 150, 3 chamber silos present with distances varying from 40 to 160 Meters. To prevent heating of the granulate we have integrated a cooler into the blower piping. With our special developed software, we are capable to the optimize the product flow for each silo and product.

Bale press

After emptying the shuttle will release the empty bags into a bag hopper, this hopper is connected to a bale press.

The horizontal compact baler press takes few space and can be mounted below the bag-emptying machine. The horizontally placed electro-hydraulic driven pressure plate, compacts the empty bags together. This ensures the continuous supply chain of the machine. This unit can make bales of approximately 300 kg. Additional plastic waste can also be thrown into the press through an inspection / access hatch.

Capacity: 3500 – 4000 bags

Every machine configuration is possible

Our machines can be configured or adapted completely according to the wishes or specifications of the customer, please contact us for the possibilities.

You can also visit our YouTube-channel for videos of this machine.